YVR Marine Fuel Delivery

The airport's existing fuel delivery system is maxed out, so Argus is working with the airlines to secure British Columbia's role as "Canada's Pacific Gateway"

To ensure a long-term competitive fuel supply for the Vancouver International Airport, a consortium of airlines is building a new delivery system that includes a marine terminal and a fuel receiving facility and a 13-kilometer underground pipeline to YVR.

Argus Consulting is providing design, consulting and construction services for the Vancouver Airport Fuel Delivery Project (VAFDP) for the Vancouver Airport Fuel Facilities Corporation.

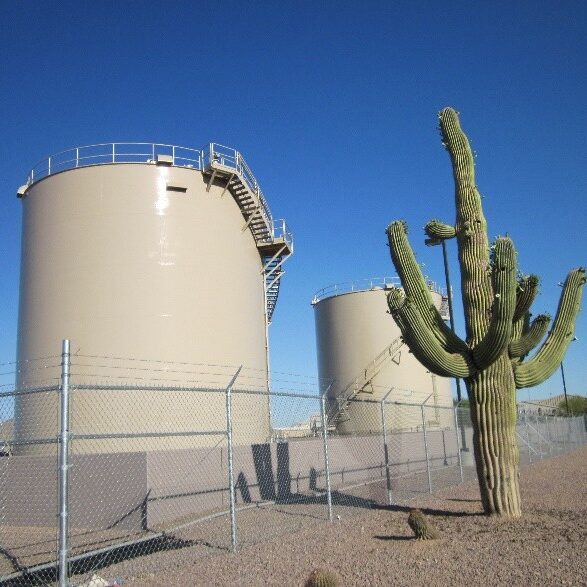

VAFFC has purchased a waterfront property on the south arm of the Fraser River. The VAFFC’s intent is to construct a deep sea vessel unloading facility, fuel storage tanks for receiving aviation fuel from the vessels, and a pipeline to existing storage facilities at the Vancouver International Airport (YVR). The system is designed to handle 100 percent of future deliveries of aviation fuel for its member airlines operating at the airport.

The VAFDP is divided into four major components: the marine terminal and ship offloading system, the new jet-fuel receiving facility, the underground delivery pipeline to Tank Farm 2 (TF-2) at YVR, and upgrades to TF-2.

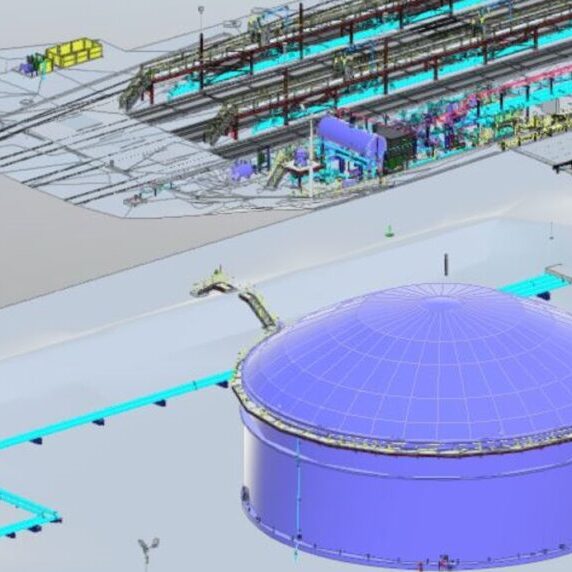

Argus used 3D modeling for virtual tours during community permit approval meetings

The new Tank Farm O (TF-0) includes the transfer pipeline from the marine terminal and inbound filtration and treatment system, six 88,000 BBL aboveground API 650 storage tanks with foundations, liner and containment dyke, containment and drainage control systems, outbound pump and filtration system, fire suppression systems, Automated Programmable Logic Control (PLC), fire water and surveillance systems, operations buildings and the access road, parking and pavement. A single pipeline will connect TF-0 to the existing fuel storage facilities at TF-2, approximately six miles (15 kilometers) away.

Upgrades to TF-2 include an inbound receiving and filtration system, PLC and controls integration with TF-0, new outbound pump and filtration system, extension of the existing utilities, relocation of the leak detection system, and a new operations building and motor control center.