Argus Places the Same Value on Safety, Environmental Concerns, and Mitigating Service Interruptions as You Do.

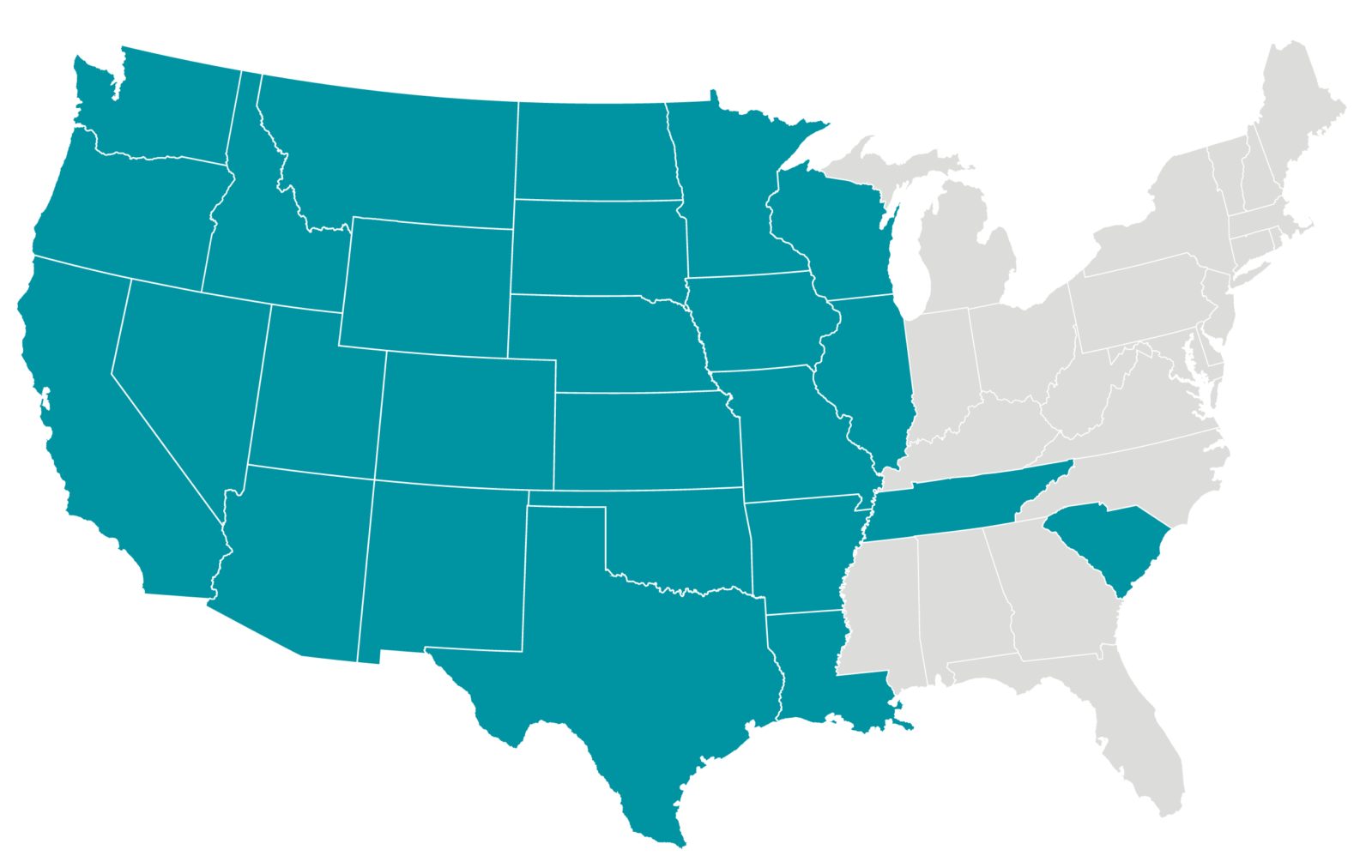

Argus offers planning, program management, engineering, asset integrity and construction administration for railroad fuel-handling facilities and systems. We also offer industrial wastewater and storm treatment services. Our approach gives you the flexibility for optimizing valuable short-term solutions, while maximizing asset life.

Our multidisciplined engineering team and cross-industry expertise give you the advantage of real-world approaches to your fuel-handling and environmental projects. We’re creative problem-solvers and understand the importance you place on reliability, cost management, and efficiency.

Who we serve:

- Class I Railroads

- Short Lines

- A/E Firms

- Construction Contractors

Your Trusted Partner for Railroad Fueling Systems

We provide design/bid/build and design/build project delivery methods for a variety of rail fueling infrastructure.

- Locomotive fuel-dispensing platforms

- Tank car and truck loading and unloading stations

- Pipeline receiving stations

- Fuel storage facilities

- Pumping stations

- Distribution piping systems

- Industrial wastewater and stormwater systems

Applying specialized experience and extensive technical competence, the Argus team delivers on plan, on time, and on budget.

Engineering Services

- Planning

- Full-service engineering and design

- Modeling

- Fuel master planning

- Fuel forecasting

- Project studies

- Modernization programing

- Code compliance analysis

- Supply chain and routing studies

- Hydraulic simulations

- Failure/risk analysis

- Fuel quality considerations

- Basis of design reports

- Product integrity

- Cathodic protection

Site Development

- Topographical surveys

- Services and utilities locations

- Component spacing compliance

- Geotechnical analysis

- Access and egress analysis

- Site planning and layout

- Demand and sizing analysis

- Permitting

Continuous performance for the lifecycle of your asset.

We know that capital and maintenance budgets are tight. Unforeseen issues or outages can be costly and disruptive. Our Asset Integrity Services care for the technical integrity, safety and reliability of your fueling facilities and equipment, therefore protecting your bottom line and reducing expensive surprises.

Inspection and Assessment Services

- Facility condition assessments

- Baseline data reports

- Asset integrity management assessments

- Motion amplification vibration analysis

- NACE coating inspections

- NACE and ASTM coating analysis

- API 510, 570, 653 inspections

- STI SP001 inspections

- In line inspection management support

- Cathodic protection design and assessments

- Thermal imaging

- Tank calibrations

- Leak detection/volumetric testing

- Security

- Pump vibration analysis

- Facility mapping

- Fire protection systems

- Operational reliability (EFSO and PLC)

- SPCC inspections

Facility Maintenance and Response Programs

- O&M manuals

- Design/operational analysis

- Engineered work directives

- Asset identification

- Out-of-service tank inspections and repairs

- Meter and gauging calibrations

- Pressure Relief Valve (PRV) testing

- Maintenance programs

- Pump alignment and repair

- Infrared/thermal imaging and repairs

- ROI studies

- Fire suppression systems testing and reliability

- Coating specifications and repair

- Environmental sampling and testing

- Routine maintenance oversight

- Operations support and training

Risk Management

- Reliability-Centered Maintenance (RCM)

- Condition-based maintenance and mitigation

- Risk prioritization

- Program management (capital and maintenance budget)

- Preventative and predictive maintenance

- Emergency response

- Contractor vetting

- Failure analysis

- Failure Modes and Effects Analysis (FMEA)

Your environmental commitments are paramount

Our environmental professionals specialize in addressing your planning, investigation, permitting, reporting and remediation concerns. We understand the complex environmental issues and priorities of rail facility owners and operators. Our foundation of traditional design expertise combined with extensive regulatory knowledge makes us a valued partner for your fuels and IW teams.

Permitting and Compliance

You don't have to worry if your operations are in compliance with current codes and standards. Our specialists do that for you while keeping the operational needs of your facility a priority.

- Spill Prevention, Control, and Countermeasure (SPCC)

- Facility Response Plans (FRP)

Environmental Systems Design

- Assessment, improvement and design

- Industrial wastewater treatment plants and collection systems

- Stormwater collection and segregation

- Geosynthetic containments

- Concrete containments

- Double-contained piping with leak detection

- Waste management systems

Environmental Support Services

It's not uncommon to encounter issues during facility upgrades and expansion projects, such as subsurface contamination, materials containing asbestos or lead paints, unstable conditions, or other abnormalities. The combined talents of the Argus design and environmental staff from project planning through construction are instrumental in guiding clients to successful completion of their projects.

Clients benefit from our proactive approach to project management.

- Demolition/decommissioning

- Commissioning/startup

- Program management

- Construction management

- Construction administration

- Construction inspection

- Budget and schedule management

- RFP development

- Capital planning

- Permitting and bidding support

- Equipment submittal and shop drawing review

- Fuel equipment and material procurement

- General contracting

- Resident engineering

- Owner’s representative

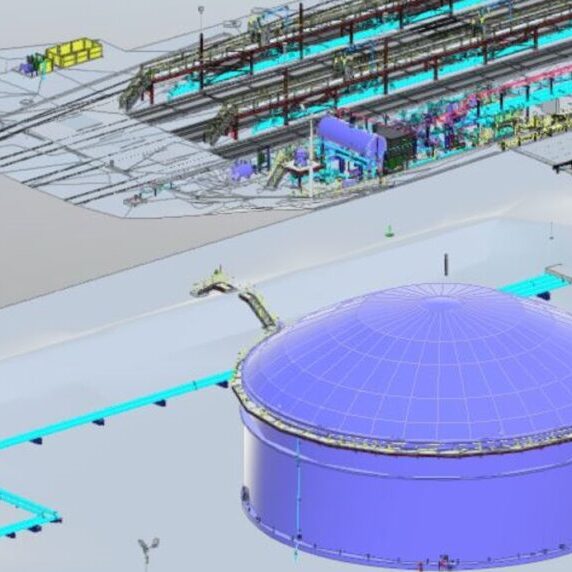

We’re developing smarter, better ways of engineering, planning and extending the life of your critical infrastructure and fueling assets.

Design and construction activities in railroad facilities require data and drawings, which are almost always missing, outdated or scattered. Modifications to brownfield facilities can be difficult due to the lack of as-built information. Travel costs for site visits, human error and uncertainty in the collected data cause inefficiency, and compliance and liability issues.

Digital engineering can be employed to survey, collect, visualize, manage and analyze the data associated with existing infrastructure. Adopting these tools provides accurate, accessible information to owners, operators, engineers, designers and inspectors throughout the life cycle of the assets.

Facility Digital Services

- LiDAR laser scanning

- Drone scanning

- Geometric 3D modeling

- Intelligent 3D modeling

- Isometrics

- Bill of materials

- Tank strapping

- Dike capacity analysis

- Parametric photogrammetry

- Ground penetrating radar

- Facility digitization

- Motion amplification vibration analysis

- Computer-based training

- Predictive maintenance

- Simulator training

- Real-time signals condition monitoring

- SAIM™ Smart Asset Integrity Management Platform

Smart Facilities

SAIM is an online portfolio of Smart Asset Integrity Management solutions harnessing the power of IoT for a real-time look at your system's performance.

Your fueling asset's "digital twin" eliminates guesswork. It is a digital replica of your whole facility, including physical and procedural assets.

Facility design, maintenance and management powered by centralized information and intelligent dashboards helps you deliver transparency, reduce risk, strengthen compliance, transfer knowledge and supports informed decision making.

Visit SAIM.com to learn more and take a facility assessment to determine your digital transformation needs.

Meet Our Team

Glen Smith, P.E.

Chief Mechanical Engineer

Jim Gorely, P.E.

Senior Civil Engineer

Steve Conway, P.E.

Associate Electrical Engineer

Jaydee Bullard, API, STI

Associate Fuels Specialist