SJC Digital 3D As-Builts

Data from digital 3D As-Builts can be used for future design projects, engineering analysis, training, and inspection projects.

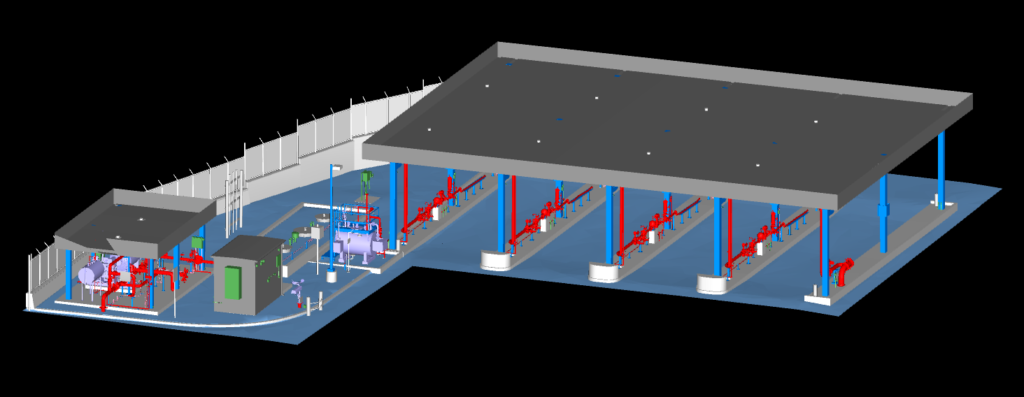

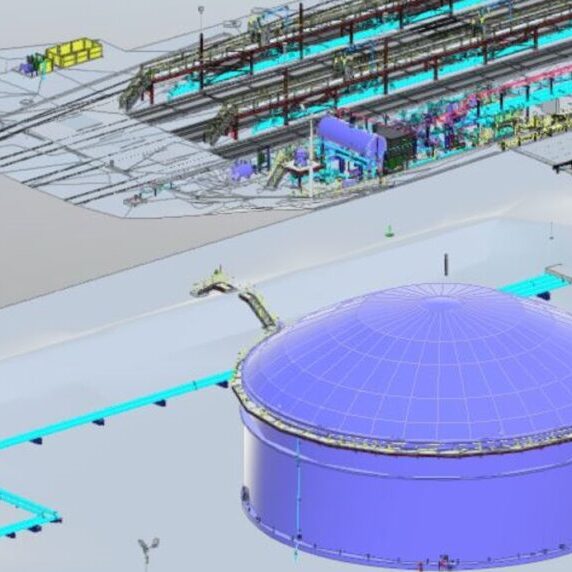

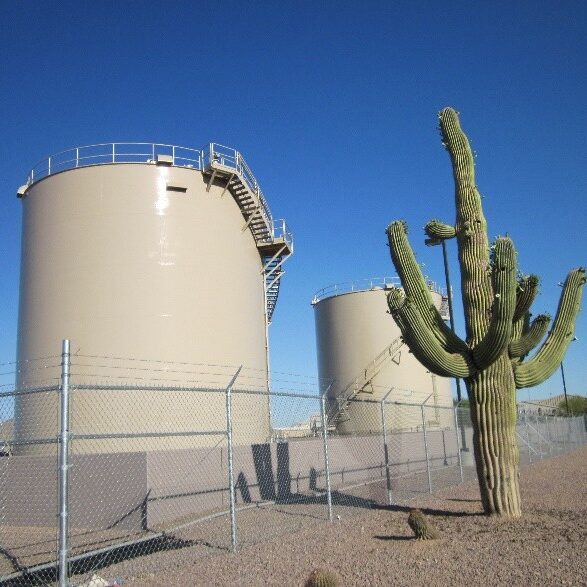

Argus created 3D geometrical scans and 3D intelligent engineering models of the tanks, process equipment, piping system, and infrastructure within San Jose International Airport Fuel Facility and the remote truck rack. The LiDAR scans were used to create 3D CAD As-Builts of the assets to be used for future upgrade projects and for creating a digital twin of the facilities for the SAIM™ Smart Asset Integrity Management platform services.

Specialized surveyors equipped with terrestrial 3D laser scanning collected full-coverage point cloud data of the equipment, aboveground piping, structures, and associated components to produce the 3D CAD intelligent models and the 3D interactive view of all assets. The scan data is of high level of accuracy eliminating human field survey errors and producing drawings based on verifiable sources of data.

Digital tools provide immediate use and value

This 3D digital twin was immediately used as the reference data for the design of a new pumping and filtration project. The digital twin allowed the team to design the new equipment with exact dimensions to mate with the existing equipment, providing the opportunity for off-site fabrication and eliminating fit-up errors during construction. It also eliminated the work of redrawing the existing 2D documents into 3D. The digital twin identified a couple of instances of missing existing equipment, allowing the team to design to accommodate and avoid construction change orders or schedule delays. When the owner desired to add additional scope later in the design, the comprehensive nature of the 3D scan allowed the design team to quickly incorporate the request without additional site visits or investigation.