Preparing Your Airport's Tank Farm Facility for Sustainable Aviation Fueling

Argus Consulting is an industry leader in designing the facilities needed to receive, store, and dispense fuel. We are often consulted on how sustainable aviation fuel (SAF) can be integrated at airports as the industry looks to decrease its carbon footprint.

“It’s our aim to help our clients reach their sustainability goals,” says Nate Spilker, Argus Western Region Commercial Aviation Business Unit Director. “We provide expertise on a wide range of aviation fuel engineering projects, including fuel system planning, design and construction programs for airports and military bases.”

When evaluating how to integrate SAF into your facility’s supply chain, Nate says to start by considering transportation logistics and the associated site requirements.

Volume availability and demand

How much hydrocarbon-based jet fuel does the airport currently use and how much are you predicted to use? How much of that could be replaced by SAF? Knowing the volume of economically available SAF will determine infrastructure requirements.

Getting SAF where it needs to go

Where is the nearest SAF supply located? How do you get it to the airport? SAF is typically produced near the feedstock (e.g., near field, forests, or food production facilities). The feedstock goes to a material processing plant, a specialty refinery, and then SAF moves on to the destination airport. It could be transported via truck, rail, marine vessel, or pipeline. Knowing your volume requirements and growth rate will help you choose the best transport option for today and in the future.

Infrastructure investment

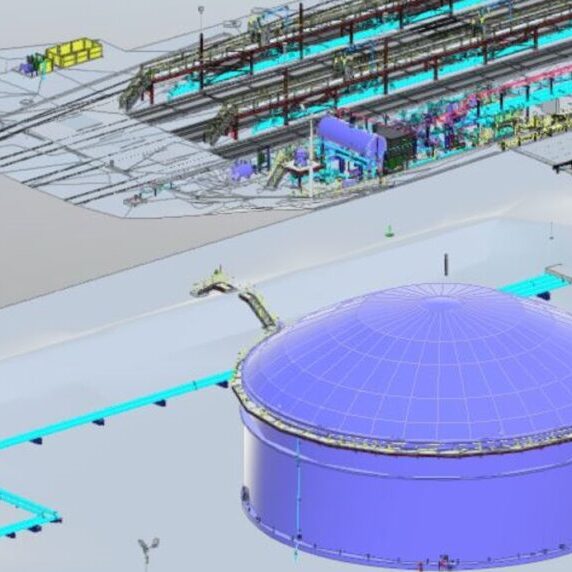

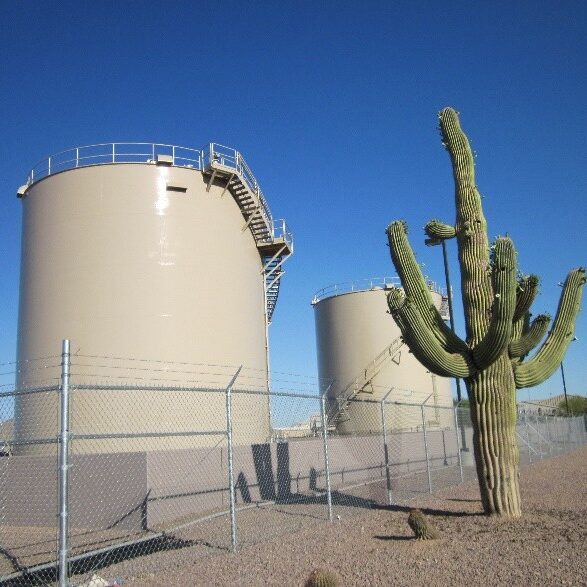

Once you know how to transport SAF to your airport, you should look at how it would be received and stored, and what components (e.g., unload racks and storage tanks) may need to be added. Keep in mind that blended SAF is a drop-in fuel, which means it can be used in existing jet fuel pipes or storage tanks without having to build entirely new infrastructure.

Fuel blending location

Another important component of both transporting the fuel and determining the necessary infrastructure investment is where to blend neat SAF (ASTM D7566) with conventional Jet Fuel (ASTM D1655) and recertify as blended SAF. Current ASTM standards allow up to 50% SAF blends for jet engines, so the logistics of both fuels merit equal consideration. Blending can happen anywhere it makes sense along the supply chain, up to onsite at the airport tank farm. However, any facilities upstream of the blend point must be capable of handling neat SAF; which prohibits using conventional jet infrastructure. Facilities downstream of the blend point do not have this restriction and can repurpose existing conventional jet infrastructure.

Nate says the considerations above are the basic building blocks of an SAF feasibility study, like the one Argus did for SEA-TAC Airport in 2016.

“Our goal was to identify the best approach to deliver SAF to the SEA-TAC fuel hydrant system, as the Port of Seattle, Alaska Airlines and Boeing wanted to make SEA-TAC one of the first to offer a reliable supply of SAF,” Nate says. “Ultimately, we identified and evaluated three site options that could support the receipt, blending, storage and delivery infrastructure required to supply SEA-TAC with SAF.”